CPO Co-Packaged Optics Technology

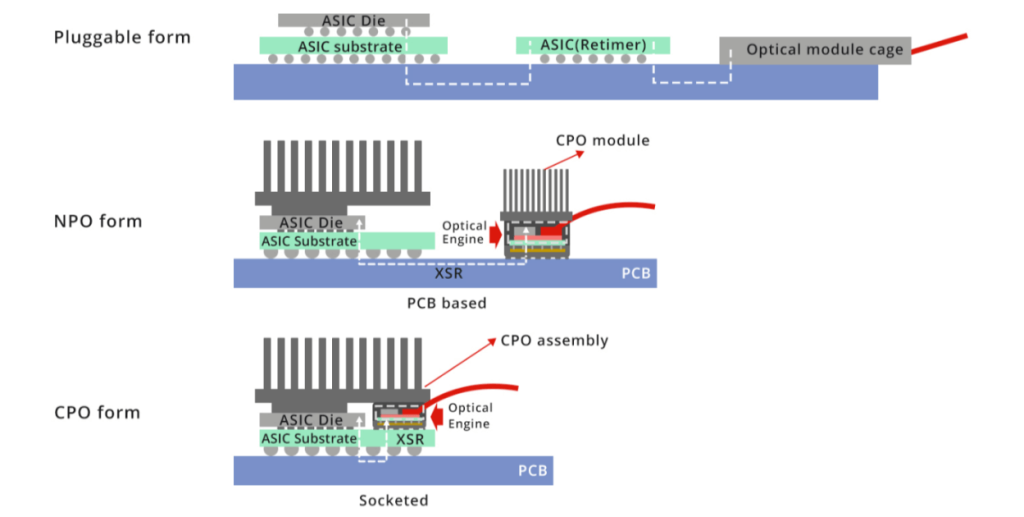

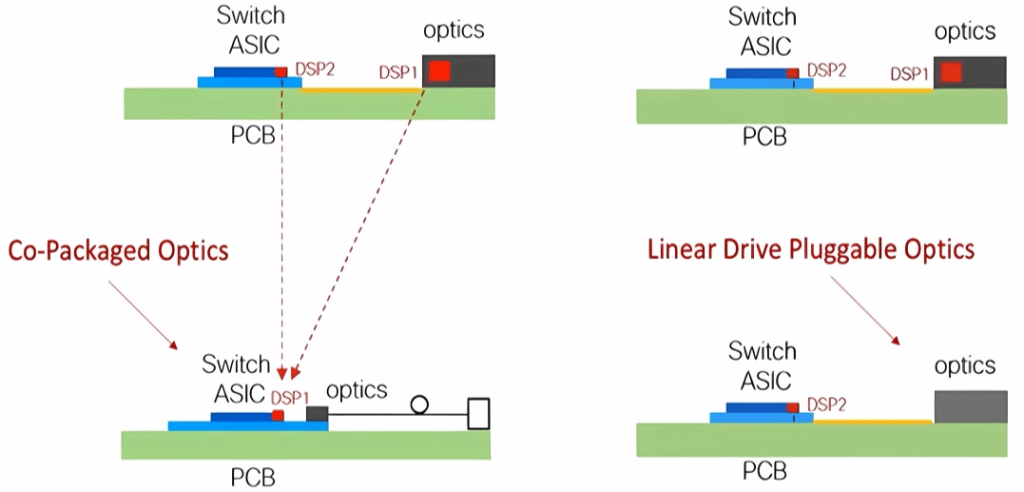

CPO, short for Co-Packaged Optics, is a solution that integrates optical modules and switch chips onto the same substrate using advanced packaging technology to achieve electro-optical co-optimization. This approach shortens electrical interconnect distances, reduces signal attenuation and power consumption, and increases bandwidth density. Its technical implementations include 2D, 2.5D, and 3D packaging, with 3D packaging achieving higher integration through vertical stacking.

The evolution of CPO technology first went through NPO (Near-Packaged Optics) and then advanced to CPO. In NPO, the optical engine and switch chip are decoupled first and then packaged together on the same system board. CPO, on the other hand, directly assembles the switch chip and optical engine onto the same substrate, achieving true co-packaging of the chip and module. Compared with NPO, CPO places the module closer to the switch chip, enabling lower power consumption and reduced channel loss.

Technical Advantages of CPO

- Low Power Consumption and High Energy Efficiency: Shortens SerDes link distance, reducing I/O power consumption by 30%–50%.

- High Bandwidth Density: Supports ultra-high speeds such as 800G and 1.6T, suitable for data center backbone networks and AI computing scenarios.

- High Reliability: Integrated design reduces external connection points, lowering the failure rate.

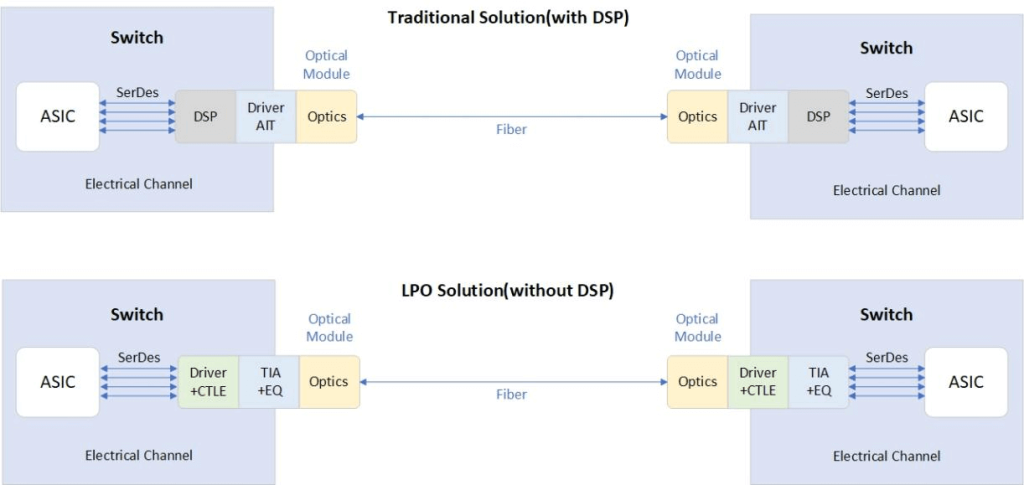

LPO Technology

LPO, short for Linear-drive Pluggable Optics, simplifies the signal processing flow by removing the DSP/CDR chip and adopting linear direct-drive technology, thereby reducing power consumption and latency while retaining the maintenance convenience of traditional pluggable modules.

Technical Advantages of LPO

- Low Power Consumption and Cost: DSP chips account for 50% of the power consumption in traditional optical modules; removing them reduces power consumption by 30%–40% and lowers material costs by 8%.

- Low Latency: Reduces signal processing steps, making it suitable for latency-sensitive scenarios such as AI training and supercomputing.

- Easy Maintenance: Retains hot-plug capability, allowing module replacement without downtime.

Comparison of Conventional Hot-Pluggable, LPO, and CPO

| Parameter | Hot-swappable | LPO | CPO |

| Power Consumption | High | Quite Low | Low |

| Cost | High | Quite Low | Low |

| Latency | High | Quite Low | Low |

| Product Maturity | Quite High | Quite Low | Quite Low |

| Maintainability | Good | Good | Hard |

| Performance | Good | Moderate | Good |

| Internet Ecology | Good | Hard | Hard |

Technical Limitations of CPO and LPO

Currently, CPO technology faces the following bottlenecks due to insufficient maturity:

- Complex packaging process: CPO packaging relies on silicon photonics integration and complex packaging techniques. The yield rate of current 3D packaging is below 80%, and multi-module integration increases the failure rate.

- Thermal management pressure: High integration leads to thermal densities up to 500W/cm², requiring liquid cooling or microchannel cooling technologies, which are costly and complex.

- Supply chain dependency: Due to the complexity of the process, CPO depends on manufacturers equipped with advanced packaging equipment. Limited production capacity may restrict large-scale deployment, and initial costs are 2 to 3 times higher than traditional solutions.

- Maintenance inconvenience and lagging standardization: The co-packaged design means that faults may require replacing the entire board, severely impacting maintenance efficiency. Although OIF and COBO have developed CPO standards, different vendors’ solutions vary, resulting in poor compatibility. Industry collaboration still needs time.

LPO technology also faces the following challenges:

- Limited bit error rate and transmission distance: Removing DSP significantly reduces power consumption but supports only short distances under 500m, unable to meet long-distance transmission requirements. The capability of 224G SerDes is questionable, potentially limiting future rate upgrades.

- Signal integrity: LPO relies on highly linear drivers and TIA chips to compensate for signal attenuation but requires stringent system-level electrical channel design, making link performance difficult to guarantee.

- Module cost reduction but increased system cost: While LPO modules are less expensive, switching ASICs must be redesigned to integrate compensation functions, resulting in no significant reduction in overall deployment cost.

Conclusion

CPO and LPO essentially represent a technology trend toward low latency and low power consumption. Leveraging ultra-high speeds and exceptional energy efficiency, CPO is poised to become a core pillar for AI supercomputing and quantum computing. Meanwhile, LPO, with its advantages in flexible deployment and incremental upgrades, dominates the market for edge nodes and terminal-to-data-center distances. Currently, pluggable optical modules remain the market mainstream, featuring excellent supply chains and efficient maintainability. With future breakthroughs in packaging technology and silicon photonics materials, the optical communication industry is set to undergo significant transformation.