A Complete Guide to Single Mode LC Connectors in Fiber Optic Networking

First of all, we must make it clear that the main principle of modern network signal transmission is optical communication, which converts the emitted optical signal into an electrical signal, and then converts the received electrical signal into an optical signal. In short, optical communication is the technology of using light to transmit information to the other party. And an important medium to accomplish this mission is optical fiber. The single-mode LC fiber optic patch cord is a key accessory for connecting optical fiber equipment in optical network communication. It consists of two parts: single-mode optical fiber and LC connector. The topic we are going to focus on today is the single-mode LC connector in optical fiber. This article will focus on the important content about single-mode LC connector from the following aspects.

What is a Single-Mode LC Connector?

First of all, the LC connector is a miniaturized fiber optic connector with a 1.25mm sealing ring inside. It is small in size, high in density, and adopts a push-pull connection method for easy operation. The LC connector is specially designed for single-mode fiber optic cables. It minimizes signal loss and interference, which is very conducive to high-bandwidth and long-distance transmission. The efficient transmission of the single-mode LC connector makes it a very reliable product for telecommunications and data centers.

What are the Specific Features and Advantages of Single-Mode LC Connectors?

- A standard two-piece design with a long-body boot ensures compactness and maximizes space efficiency in high-density environments.

- Advanced manufacturing processes ensure minimal optical signal loss during the coupling process, resulting in high transmission efficiency.

- A push-pull quick-connect mechanism simplifies installation and removal, enhancing ease of operation and improving work efficiency.

- Made of high-quality materials, the LC connector maintains stable performance and resistance to damage during repeated connection and disconnection, ensuring excellent reusability.

- Widely applicable, it is suitable for various fiber optic communication systems, offering exceptional value for money.

How Does the Single-Mode LC Fiber Optic Connector Work in Optical Communications?

The primary function of a fiber optic connector is to act as a removable medium between an optical fiber and a fiber optic connector. It allows for quick connection between two optical fibers, ensuring a continuous optical path for optical signals. Fiber optic connectors precisely connect the two end faces of an optical fiber, maximizing the coupling of light energy from the transmitting fiber into the fiber, forming an optical link and minimizing system impact.

A core component of a fiber optic connector is the ferrule. The quality of the ferrule directly affects the precise centering of the two optical fibers. Ferrules can be made of ceramic, metal, or plastic. Currently, the most widely used is the ceramic ferrule. Ceramic ferrules play a critical role in maintaining the performance and reliability of fiber optic connectors, making them essential components in telecommunications and data communication systems. Made of zirconium dioxide, they feature high hardness, a high melting point, wear resistance, high precision, and excellent thermal stability.

Another key component of a fiber optic connector is the sleeve, which serves as an alignment mechanism to facilitate connector installation and securement. The inner diameter of the ceramic sleeve is slightly smaller than the outer diameter of the ferrule. The slotted sleeve clamps the two ferrules together, ensuring precise alignment. In order to make the end faces of the two optical fibers contact better, the end faces of the ferrules are usually polished into different structures. PC, APC, and UPC represent the front face structures of the ceramic ferrules. PC stands for Physical Contact. PC is a micro-spherical grinding and polishing process, and the surface of the ferrule is ground into a slightly spherical surface. APC (Angled Physical Contact) is called an angled physical contact, and the end face of the optical fiber is usually ground into an 8° angle. UPC (Ultra Physical Contact) is an ultra-physical end face. UPC further optimizes the end face polishing and surface finish on the basis of PC, and the end face looks more dome-shaped. These can further hinder signal reflection and optimize output by working on the contact surface of the sealing ring.

The optical performance requirements for fiber optic connectors primarily focus on two basic parameters: insertion loss and return loss. Insertion loss is the loss of the connection (connector insertion) that impairs the effective optical intensity. To ensure stable and high-speed optical signal transmission, insertion loss should be as low as possible and should not exceed 0.5dB. Return loss (reflection loss) refers to the reduction in the intensity of the light emitted by the connector in the link and is typically no less than 45dB.

In this context, the LC fiber optic connector stands out among other connectors. The LC’s pin and ferrule dimensions are 1.25mm, which increases the density of optical front connectors on fiber optic distribution frames. Furthermore, it offers low insertion loss of less than 0.3dB and high return loss of over 50dB. Furthermore, the LC fiber optic connector uses standard ceramic ferrules, which can be bonded with any adhesive, making it highly reusable.

What are the Different Types of LC Fiber Optic Connectors? What are the Differences Between Them?

LC fiber optic connectors can be divided into single-mode and multi-mode LC connectors from the perspective of lasers. From the perspective of fiber channels, they can also be divided into duplex LC connectors and simplex LC connectors.

What are the Main Differences Between Multimode LC and Singlemode LC?

Like modules, LC is divided into two types: multimode and single-mode. So what are the main differences between the two?

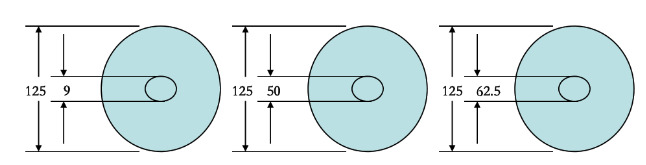

Fiber Core Diameter

The main difference between multimode and single-mode fiber is that the former has a larger diameter, usually a core diameter of 50 or 62.5, while the former has a core diameter of 0.5, and the cladding diameter of both is 125. This difference also changes the way light propagates through the fiber.

Transmission Form

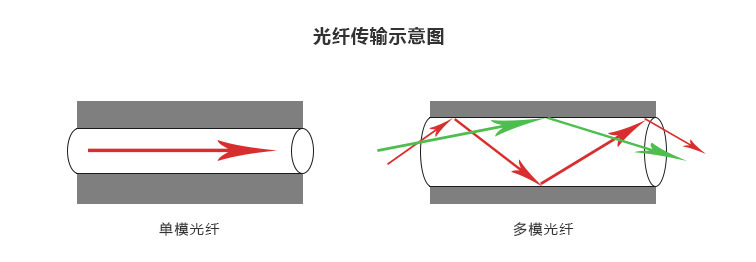

Single-mode fiber transmits light along the fiber’s core, minimizing dispersion and wasted optical energy.

Multimode fiber transmits light continuously along the fiber’s edges, resulting in significant dispersion and wasted optical energy.

Transmission Distance

Multimode LC fiber is primarily used for short-distance fiber optic communications, such as within buildings or on campuses. It typically transmits at a speed of 100 m/s over distances up to 2 km (100BASE-FX). 1G/s transmission speeds can reach 1000 m/s, and 10G/s transmission speeds can reach 550 m/s.

Single-mode fiber supports longer transmission distances than multimode fiber, exceeding 5000 m.

Different Wavelengths

Multimode fiber operates at shorter wavelengths such as 850nm and 1310nm, while single-mode fiber operates at longer wavelengths of 1310nm and 1550nm.

The Difference in Cost

Single-mode fiber uses a solid-state laser as its light source, while multimode fiber uses a light-emitting diode. The lasers used in multimode LC connectors are less expensive than those used in single-mode LC connectors. However, single-mode LC connectors offer superior performance over multimode systems over long distances.

Different Application Scenarios

Single-mode LC connectors are commonly used in telecommunications and large-scale networks, while multimode LC connectors are mostly used in local area networks and data centers.

What are the Main Differences Between Duplex LC and Simplex LC?

A simplex connection means that the signal is sent in one direction—a signal is transmitted from device A to device B via two simplex connectors and a simplex fiber optic cable, but cannot be returned from device B to device A via the same route. This allows data to travel in one direction only. Simplex LC fiber optic connectors typically connect a single glass or plastic optical fiber and are commonly used in systems that only transmit data in one direction.

A duplex connection means that the signal can transmit and receive data in both directions simultaneously. A duplex fiber optic connector connects two optical fibers. It is often used for other network-related activities.

How to Install LC Connector on Fiber Optic Cable?

- Tool Preparation. Ensure the work area is clean and gather the necessary tools and materials, including LC fiber connectors, pre-optical strippers and cleavers, cleaning tools, alcohol wipes, cleaning pens, a fusion splicer, and inspection equipment (power meter, optical time domain reflectometer).

- Fiber Stripping. Use a fiber stripper or specialized cleaver to carefully strip the protective layer from the optical fiber to expose the core, ensuring the core is clean and free of contaminants.

- Fiber Cleaning. Use alcohol wipes or a fiber cleaning pen to clean the surface of the fiber core, removing dust and fingerprints, and ensuring the core is dry and dust-free.

- Fiber Insertion. Carefully insert the cleaned fiber core into the LC fiber connector, ensuring it is fully inserted into the connector and aligned with the internal metal contact surface. Use the fiber insertion tool (V-groove clamp) to secure the fiber securely in the connector.

- Connector Inspection. Use a magnifying glass to inspect the fiber connection to ensure it is fresh, unbent, or damaged, and properly aligned with the connector’s metal contact surface. Use a power meter to test the connection for signal loss to ensure it is within acceptable limits.

- Secure the fiber. Place the connected LC fiber in a suitable patch panel and secure it with screws, ensuring that the fiber remains stable and does not move.

How to Install LC Fiber Optic Connectors?

- Remove the dust cap from the LC fiber optic connector and store it properly for next use.

- Align the two connectors to ensure that the center pins are on the same axis and the pins and slots are in the same direction.

- Align the fiber optic adapter along the axis and gently push the fiber optic plug.

- When you hear a click, the connector is in place. The hook pops up and locks in place, ensuring it is easy to remove. The installation is complete.

- To remove the connector, gently press the button on the fiber optic plug to disengage the hook from the slot. Gently pull the fiber optic plug housing along the axis to complete the removal.

How to Maintain LC Connectors for Optimal Performance?

Connector cleanliness is very important to ensure optimal performance and signal quality. Maintenance and cleaning are equally important. Dust, oil, and other debris on the surface of the connector can cause signal attenuation or damage.

- Deep cleaning

Tool selection: Special fiber optic cleaning pen/box, dust-free microfiber cloth, and isopropyl alcohol cleaner to deal with stubborn stains. Technique specification: One-way linear wiping (non-rotating), no more than 3 round trips per cleaning. Note: Compressed air is prohibited (it is easy to retain water vapor) and re-use of cleaning paper is avoided. - End face inspection

Before cleaning, use a microscope (200x+) to identify the type of contamination. After cleaning, re-inspect to ensure that there are no residual scratches/debris. Before docking, conduct a second visual inspection to confirm that the ferrule is free of new contamination. - Anti-contamination operation

Wear anti-static gloves when handling and hold the connector shell throughout the process. Keep the dust cap closed before docking and keep it away from your hands for less than 15 seconds. Do not touch the end faces against each other (even with dust caps). - Dust protection

Short-term: dust cap + self-sealing anti-static bag

Arrangement: Use figure-8 winding for pigtails to avoid excessive bending - Regular inspection

Performance inspection every 6 months (IL/RL value comparison benchmark), mandatory replacement when plugging and unplugging exceeds 500 times or end face wear is found, establish connector usage records, and track contamination/loss trends.

Frequently Asked Questions (FAQ)

Q: What is a single-mode LC connector?

A: The single-mode LC connector is a connector designed to terminate single-mode fiber optic cables due to its compact size.

Q: Do single-mode connectors work with multimode cables? Can I use single-mode LC connectors with multimode modules?

A: You can use single-mode connectors on multi-mode cables, but single-mode connectors cannot be used with multi-mode modules. Single-mode optical fibers are best used with single-mode optical modules because the converters for single-mode and multi-mode must have corresponding wavelengths and optical transceiver functions to achieve photoelectric conversion. Therefore, using multi-mode optical fibers with single-mode optical modules cannot guarantee effective use.

Q: What types of fiber optic connectors are available on the market?

A: Common fiber optic connectors include FC fiber optic connector, SC fiber optic connector, ST fiber optic connector, and LC fiber optic connector.

Q: I installed an SC connector, but later realized I needed an LC type. What should I do?

A: If this is the case, a common solution is to buy an SC-SC coupler and then a pre-terminated SC to LC patch cord. There are also adapters such as LC-LC or LC-SC.

Q: How do single-mode LC connectors differ from SC connectors?

A: SC fiber optic patch cord connectors utilize a ferrule diameter twice as large as that of LC patch cords (2.5mm), hence the name “large square” fiber optic patch cord. Compared to the latching mechanism of LC jacks (RJ), these patch cords utilize a push-pull design for plug-and-play installation. SC fiber optic patch cord connectors are ideal for telecommunications and data network systems, as well as passive optical networks.

Q: Where are single-mode fiber and multimode fiber used?

A: Single-mode fiber enables optical fiber to be emitted directly to the center and is generally used for long-distance data transmission; in multimode fiber, optical signals are transmitted through multiple paths, so multimode fiber is often used for short-distance data transmission.

In This Article

- 1 What is a Single-Mode LC Connector?

- 2 What are the Specific Features and Advantages of Single-Mode LC Connectors?

- 3 How Does the Single-Mode LC Fiber Optic Connector Work in Optical Communications?

- 4 What are the Different Types of LC Fiber Optic Connectors? What are the Differences Between Them?

- 5 How to Install LC Connector on Fiber Optic Cable?

- 6 How to Install LC Fiber Optic Connectors?

- 7 How to Maintain LC Connectors for Optimal Performance?

- 8 Frequently Asked Questions (FAQ)

Show All

Collapse