All You Need to Know About Fiber Optic Cable Cores

The birth of optical fiber cores is to solve the speed and distance limitations of traditional cables in data transmission. In the 1960s, due to the advancement of technology and the growth of communication demands, people began to seek new communication technologies. The core of optical fibers is the core component of optical fibers. Its emergence has greatly enhanced the speed and quality of data transmission.

Overview of Optical Fiber Cores

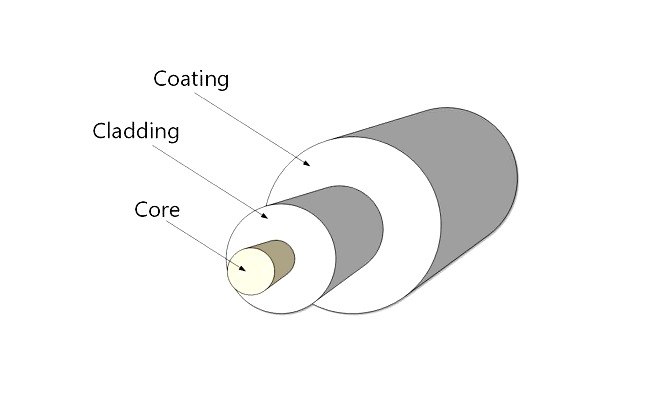

Composition of Optical Fiber Core

Optical fibers are mainly composed of three parts: the core, the cladding and the protective layer. The core serves as the channel for optical signal transmission, with a diameter typically ranging from 8 to 62.5 micrometers, and is made of high-purity silicon dioxide (SiO2). The cladding wraps around the core, with a refractive index slightly lower than that of the core, ensuring that the light signal propagates through total reflection. Its diameter is approximately 125 micrometers. The outer protective layer is usually made of acrylic resin or polyimide to prevent physical damage to the optical fiber.

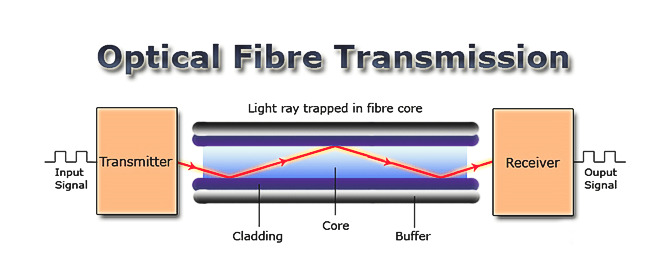

Working Principle of Optical Fiber Core

The working principle of optical fiber cores is mainly based on the principle of total reflection. When light enters a low refractive index medium from a high refractive index medium, if the incident Angle is greater than the critical Angle, the light will be completely reflected back to the high refractive index medium. In optical fibers, the refractive index of the core is higher than that of the cladding. Therefore, when light propagates in the core, total reflection occurs, thus enabling long-distance optical signal transmission.

Main Types of Optical Fiber Cores

Classification by transmission mode

According to the transmission mode, they can be classified into single-mode optical fibers and multi-mode optical fibers. Single-mode optical fibers have a small core diameter (8-10μm), allowing only single-mode optical transmission, with low attenuation (0.2-0.4dB/km), and are suitable for long distances (over 100km). They are typically applied in scenarios such as telecommunication backbone networks, submarine optical cables, and 5G base stations.

Multimode optical fibers have a large core diameter (50/62.5μm), allowing for multimode optical transmission. They have a relatively high attenuation (2-5dB/km) and are suitable for short distances (≤2km). They are typically used in local area networks (Lans), data centers, monitoring systems, and other scenarios.

Classification by Material

According to the material classification, it can be divided into glass optical fibers and plastic optical fibers. Glass optical fibers with high-purity SiO2 and low loss are used for long-distance communication. Plastic optical fiber (POF) is low in cost and easy to install, but it has high loss. With the development of The Times, plastic optical fiber has been replaced by glass optical fiber.

Special Types of Optical Fibers

According to the special types of optical fibers, they can be classified into anti-bending optical fibers and erbium-doped optical fibers. Bent-insensitive Fiber (BIF) is suitable for complex cabling environments such as FTTH. Erbium-doped fiber (EDFA) is used for amplifying optical signals and enhancing long-distance transmission capabilities.

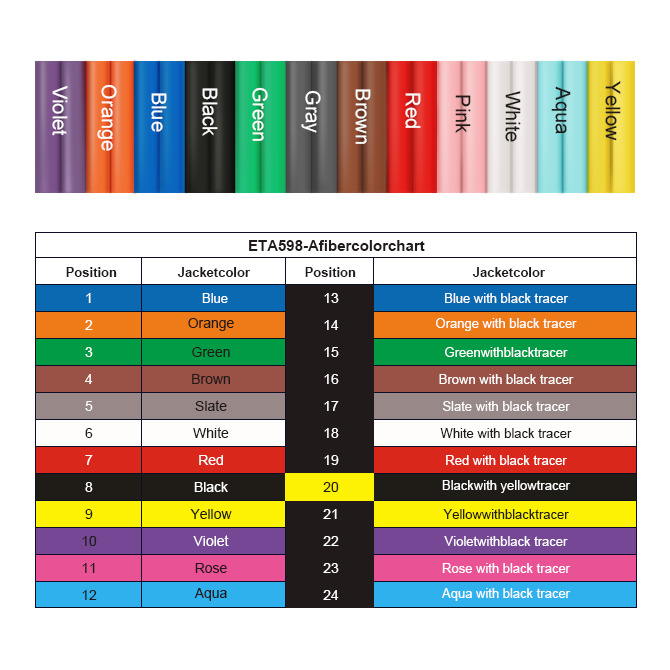

What Are the 12 Core Fiber Colors of Optical Fibers?

The 12 core colors of standard optical fiber cables are blue, orange, green, brown, grayish blue, white, red, black, yellow, purple, rose red and light green.

Key Performance Indicators of Optical Fiber Cores

Attenuation

Attenuation is a standard for measuring the loss of optical signals during transmission, and its unit is expressed in dB/km. The typical values for single-mode optical fibers are 0.35dB/km (at a wavelength of 13100nm) and 0.2dB/km (at a wavelength of 1550nm). The typical values of multimode fibers are 2 to 3.5dB/km (at a wavelength of 850nm) and 0.6 to 1.0dB/km (at a wavelength of 13100nm).

Bandwidth

Single-mode optical fibers have extremely high bandwidth (>100 GHZ · km), while multimode optical fibers are limited by mode dispersion (typically 100 MHZ · km to 10GHz · km).

Dispersion

Dispersion refers to the phenomenon where light waves of different frequencies or modes in an optical fiber travel at different speeds within the fiber, resulting in the broadening of optical pulses. Dispersion is classified into four types: mode dispersion, material dispersion, waveguide dispersion, and polarization mode dispersion. Its essence is the time-domain distortion of optical signals, manifested as the dispersion of signal energy, the intensification of inter-symbol interference, which limits the transmission distance and rate. It is one of the core challenges in high-speed optical fiber communication.

How Many Cores Does an Optical Fiber Cable Have?

Optical fiber cables can be single-core or multi-core. As the number of cores in a cable increases, the amount of data that can be transmitted simultaneously will also be greater.

Single-Core Optical Fiber Cable

It has only one core and is very suitable for long-distance communication. This type of cable can be used in telecommunication networks, medical lasers, military communications and industrial automation.

Dual-Core Optical Fiber Cable

Dual-core optical fibers are most suitable for the simplest connections, such as point-to-point links between two devices. This configuration is typically used for basic home networks and short-range communication.

Multi-Core Optical Fiber Cable

Multi-core optical fiber cables are innovative optical transmission media that integrate multiple independent cores within a single optical fiber cladding, breaking through the capacity limits of traditional optical fibers. Common types include 4-core, 8-core, 12-core, 24-core, etc. Currently, the maximum high-density transmission can reach 288 cores.

How Many Cores of Optical Fiber Cable Do I Need?

The number of optical fiber cores mainly depends on the number of device interfaces and the type of communication. It is usually calculated by multiplying the total number of interfaces by 2 and adding 10% to 20% redundancy. If the device adopts serial communication or multiplexing technology, the number of cores can be reduced. According to the IBDN standard, in regular scenarios, it is recommended that each building’s communication machine room have 12 cores and the building’s machine room have 24 cores. The specific requirements depend on the number of switches and connection methods: if the core switch is dual-machine hot standby redundancy (two machines working simultaneously), 6 cores are needed (2 cores per machine +2 cores of redundancy), and a single switch needs 4 cores, with an additional 4 cores of redundancy after multiplying the total number by 4. The number of terminal points is usually equal to the number of wire cores, but in actual design, redundancy needs to be considered. It is recommended that each terminal use a maximum of 2 cores. When cost control is needed, the entire line can be redundant by 1-2 cores (for example, 3 fiber access switches use 4-core optical cables, as odd-core optical cables are rare). It should be noted that when single-core optical fibers are connected in series with multiple terminals, they need to be spliced multiple times. This may lead to severe signal loss over long distances due to excessive light attenuation. Therefore, long-distance applications should be avoided.

Common Problems and Maintenance of Optical Fiber Cores

Signal Interruption or Complete Lack of Light

The possible causes include construction damage, animal gnawing or natural disasters leading to optical fiber breakage, connector contamination or damage, and failure of optical module fusion joints, etc. The inspection can be carried out by using a red light pen for preliminary detection to confirm whether the optical fiber is transmitting light, using an OTDR (Optical Time Domain Reflectometer) to precisely locate the break point, cleaning or replacing the damaged connector, checking the working status of the optical module, replacing it if necessary, resplicing the break point or replacing the damaged optical cable section, etc.

Excessive Signal Attenuation

The possible reasons are that the optical fiber is overly bent or the bending radius is too small, the connector end face is contaminated, the splicing loss is too high, the optical fiber is aged, and the transmission distance exceeds the design range. The inspection can be carried out from aspects such as checking the optical fiber cabling to ensure that all bending radii are greater than 5cm, cleaning the connector end faces with professional cleaning tools, resplicing high-loss points to ensure that the splicing loss is less than 0.1dB, testing the optical fiber attenuation coefficient to confirm whether it meets the standards, and considering adding optical amplifiers (such as EDFA) to extend the transmission distance.

Unstable Signal Quality

The possible reasons are that the optical fiber is affected by mechanical vibration, temperature changes cause alterations in the optical fiber’s characteristics, electromagnetic interference (when laid in parallel with strong current cables), loose connectors, etc. The inspection can be carried out from aspects such as reinforcing the fixed points of optical fibers, reducing the influence of vibration, choosing optical fibers with stable temperature characteristics (such as those with a temperature resistance of -40℃ to 85℃), re-planning the routing path, avoiding parallelism with power lines, and checking and tightening all connectors.

In This Article

- 1 Overview of Optical Fiber Cores

- 2 Main Types of Optical Fiber Cores

- 3 What Are the 12 Core Fiber Colors of Optical Fibers?

- 4 Key Performance Indicators of Optical Fiber Cores

- 5 How Many Cores Does an Optical Fiber Cable Have?

- 6 How Many Cores of Optical Fiber Cable Do I Need?

- 7 Common Problems and Maintenance of Optical Fiber Cores

Show All

Collapse