How LSOLINK Tests Optical Transceivers to Ensure Quality and Compatibility?

The development of optical communication technology has promoted optical modules to become the core components of data centers and modern communication networks. Their performance and compatibility have a significant impact on the entire system. At LSOLINK, we have a complete set of testing systems for optical modules to ensure the high quality and wide compatibility of the optical modules we produce. The following will introduce to you in detail what tests LSOLINK optical modules must go through.

Hardware Test

Spectral Analysis

Spectral analysis of optical modules is an important step in evaluating the spectrum characteristics of optical signals. It is mainly used to verify whether the core indicators of the laser wavelength, spectrum width, side mode suppression, etc. in the optical module meet the design specifications. Generally, instruments such as spectrum analyzers are used to measure the central wavelength of optical modules.

Bit Error Rate Test

The bit error rate test is used to evaluate the accuracy of optical modules in transmitting data under specific conditions. This test simulates actual transmission scenarios and uses precise equipment such as bit error meters to ensure that the bit error rate of our optical modules meets industry standards.

High and Low Temperature Aging Test

High and low temperature aging test verifies the reliability and stability of optical modules in long-term use by simulating extreme temperature environments. The test accelerates material aging under extreme temperature conditions, monitors data in real time, and verifies the working performance of optical modules in extreme environments and predicts their service life in combination with failure analysis.

Endface Test

The end face test is mainly for the end face of the optical fiber connector. Any contamination or scratches on the end face will cause optical signal transmission loss. At LSOLINK, testers usually use optical microscopes and end face testers to check whether there are dust, oil, fingerprints and other pollutants on the end face. At the same time, the curvature radius, vertex offset, and angle polishing are measured by end face interferometer. If the above test items meet the standards, it means that the end face test of the optical module is qualified.

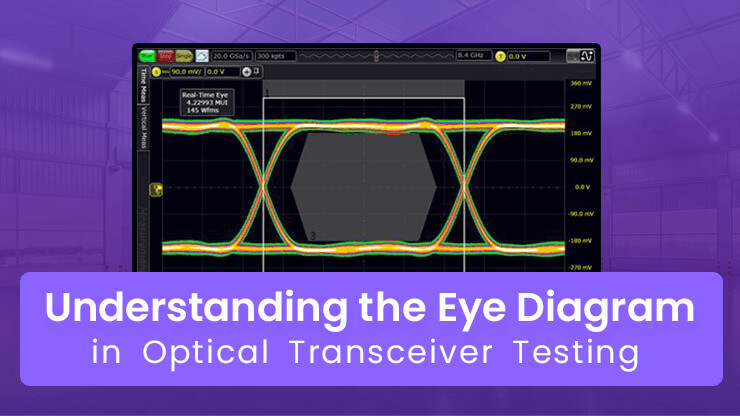

Eye Diagram Test

The eye diagram is a pattern formed by accumulating multiple signal cycles on an oscilloscope, and its shape is similar to that of an eye. This test analyzes the integrity of the signal by observing the unfolding of the signal waveform in the time domain, thereby evaluating the signal quality of the optical module when transmitting data.

Compatibility Test

Compatibility test is a key step to ensure that optical modules can operate stably under different manufacturers’ equipment and protocol standards. Each optical module of LSOLINK undergoes compatibility quality testing to ensure perfect operation. The detailed test contents are as follows.

Connectivity test: The tester uses a jumper to connect the optical module to verify whether the device port LED lights up normally and whether the port rate meets the standard.

Parameter test: The tester reads the PN, VN, SN and other information of the optical module on the device to verify that it is consistent with the description on the optical module label.

DDM test: The tester reads the module DDM information through the device management interface to monitor whether the five DDM parameters of the module exceed the threshold.

Quality Control

LSOLINK adopts advanced quality management solutions. Each transceiver undergoes self-inspection, including 20x microscope inspection, 200x microscope inspection and QC process inspection. From material procurement, production to advanced laboratory testing, LSOLINK’s comprehensive quality control system demonstrates its commitment to quality. The following will introduce you to our quality control process in detail.

IQC inspection: Incoming material inspection is the primary quality control link in the production process of optical modules. LSOLINK’s quality inspectors will conduct comprehensive inspections on raw materials and components before production to ensure that they meet design specifications and industry standards, and prevent unqualified raw materials from entering the production line.

IPQC inspection: Process inspection is a real-time quality monitoring link in the manufacturing process of optical modules. This test ensures that the product meets design specifications and process standards at every stage of production through inspection and testing of key processes. Quality inspectors will perform sampling inspections and record analysis data at the inspection nodes set in the production process. When abnormalities are found, they can intercept and correct them in time to reduce batch defects and improve product quality.

OQC inspection: Shipping quality inspection is the final quality control link before the optical module leaves the factory. LSOLINK’s quality inspectors will verify the compliance of product appearance, performance and packaging through a combination of sampling inspection and full inspection to ensure that the product meets all technical specifications, industry standards and customer customization requirements before delivery to customers.

LSOLINK’s commitment to quality is recognized worldwide. Through certification by leading international organizations, we ensure that every product delivered meets the highest standards.