Fiber Connector Overview

What is a Fiber Connector

Fiber connectors are the “bridge” that connects optical fibers or devices to optical fibers. They precisely connect the two end faces of the optical fibers to ensure that the optical signal can be stably transmitted from one fiber to another, while ensuring that the connection insertion loss is minimized (this is the most important parameter of fiber optic connectors). To a certain extent, fiber optic connectors affect the reliability and performance of the optical transmission system.

The Role of Fiber Connectors in the Network

Fiber connectors are essential components in fiber optic communication systems. They are primarily used to create precise physical connections between optical fibers, enabling efficient and stable transmission of optical signals. By using precision components such as ceramic ferrules, fiber connectors align the end faces of two optical fibers at the submicron level, minimizing signal loss and suppressing reflection. As removable and active interfaces, they support quick connections and disconnections between optical fibers and devices (such as switches and optical modules), or between fiber links themselves. This allows for flexible networking and significantly enhances the efficiency and reliability of network deployment and maintenance.

Main Types of Fiber Connectors

To meet the diverse needs of different environments and applications, fiber connectors come in a wide variety of types. Based on physical structure, common types include FC, SC, ST, LC, MT-RJ, MPO/MTP, MU, DIN, E2000, SMA, BICONIC, and CS. However, in actual network deployments, the most commonly used connectors are LC, SC, FC, ST, and MPO/MTP. These five types strike the best balance between performance, cost, and ease of use. Other connector types tend to be either structurally complex or protected by proprietary designs, making them more expensive and less practical for widespread use. As a result, they are rarely seen in modern network construction or in everyday applications.

Comparison of Technical Parameters of Fiber Connectors

Different fiber connectors have different technical parameters and usage environments. You can see the specific differences in the table below. Of course, because there are too many fiber connectors and many of them are not commonly used, here we only list the most common LC, SC, FC, ST, MTP/MPO connectors.

| Type | Mechanical dimensions | Connection method | Connection firmness | Cost | Applicable rate | Follow standards |

| LC | 1.25mm | Plug-in latch type | Middle | Low | 1G-800G | IEC 61754-20 |

| SC | 2.5mm | Plug-in latch type | Middle | Low | 1G-10G | IEC 61754-4 |

| FC | 2.5mm | Turnbuckle | High | High | 1G-10G | IEC 61754-2 |

| ST | 2.5mm | Screw buckle | High | High | 1G-10G | IEC 61754-13 |

| MPO/MTP | 2.5mm | Plug-in latch type | Middle | High | 40G-800G | IEC-61754-7EIA/TIA-604-5 |

LC Fiber Connector

The Lucent Connector (LC) is a compact fiber connector featuring a 1.25mm ferrule and sleeve—only half the size of standard connectors like SC and FC. This small form factor allows for higher cabling density, making it ideal for modern fiber optic infrastructure. Its push-pull latch design ensures easy insertion and removal, simplifying installation and maintenance. Thanks to its space-saving design and user-friendly features, the LC connector has become increasingly popular in communication applications and now dominates cabling systems in data centers.

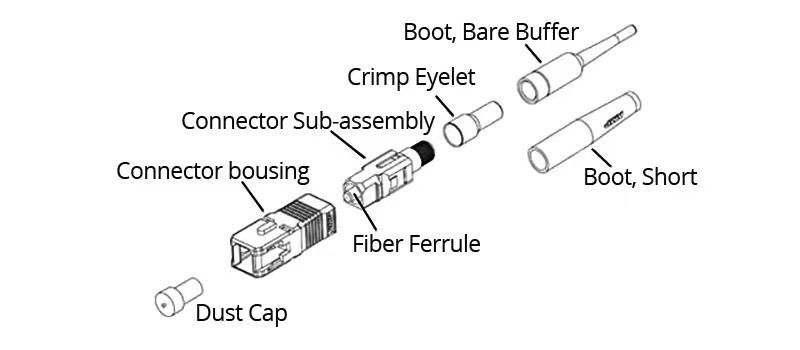

SC Fiber Connector

The Standard Connector(SC) features a 2.5mm ferrule and a convenient push-pull latch mechanism that ensures secure and reliable connections. Made entirely of durable engineering plastic, it offers low cost and long service life, making it an ideal choice for fiber-to-the-home (FTTH) applications. However, due to its larger size, the SC connector is not well-suited for high-density environments such as data centers, where space-saving designs like LC connectors are preferred.

FC Fiber Connector

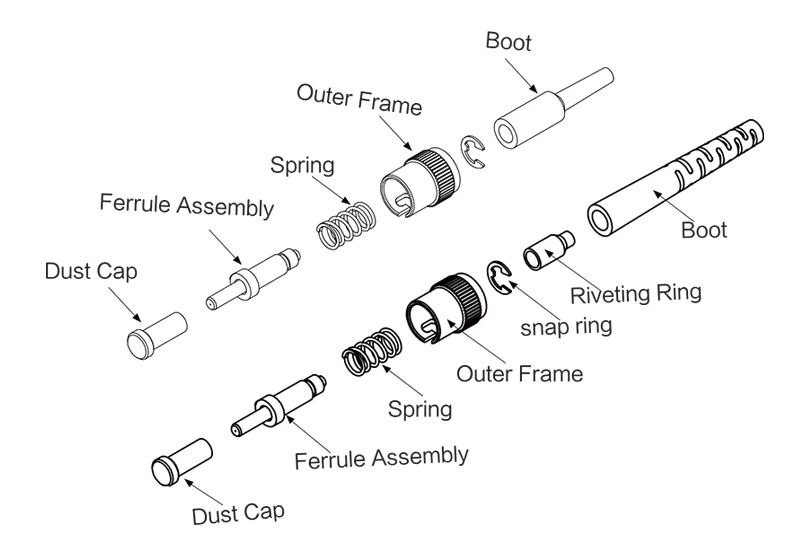

The FC (Ferrule Connector) features the same 2.5mm ferrule size as the SC connector, but differs in its construction and fastening mechanism. It uses a metal outer shell and a screw-on locking design, which provides a more secure and stable connection once tightened—eliminating the risk of loosening over time. Compared to the push-pull latch mechanism used in SC and LC connectors, the FC offers superior mechanical stability. However, its higher cost and more complex installation process make it less suitable for large-scale cabling projects. Instead, the FC connector is well-suited for environments with vibration or movement, and is widely used in industrial applications where reliability is critical.

ST Fiber Connector

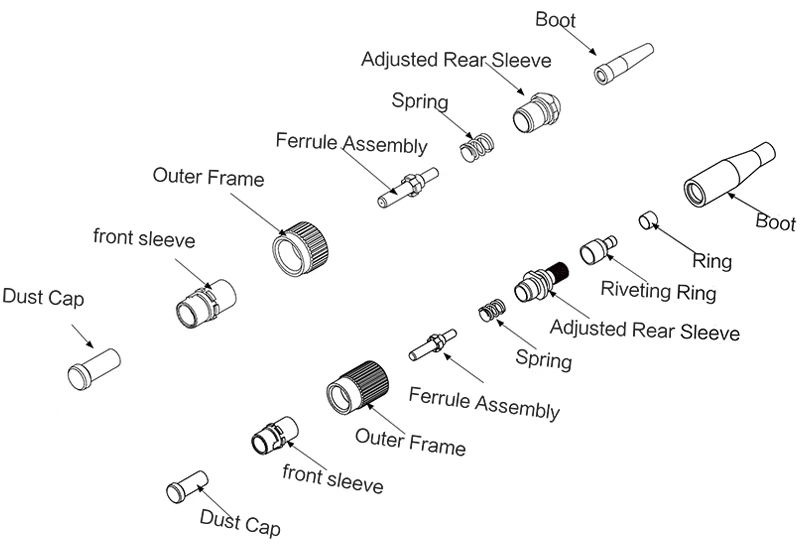

The ST (Straight Tip) connector features a round housing and a 2.5mm ferrule, similar in size to SC and FC connectors. Its outer shell is typically made of circular plastic or metal, and it uses a twist-lock mechanism that makes installation and removal easier than that of the FC connector. At first glance, it closely resembles the FC connector, but the ST ferrule is noticeably longer, making it easy to distinguish between the two. Despite its functional design, the ST connector comes with some drawbacks. It is more expensive than the LC connector, less convenient to install, and offers lower connection stability compared to the FC. Additionally, the longer ferrule increases the risk of breakage, which limits its suitability for large-scale deployment. These factors have contributed to its declining popularity in modern network environments.

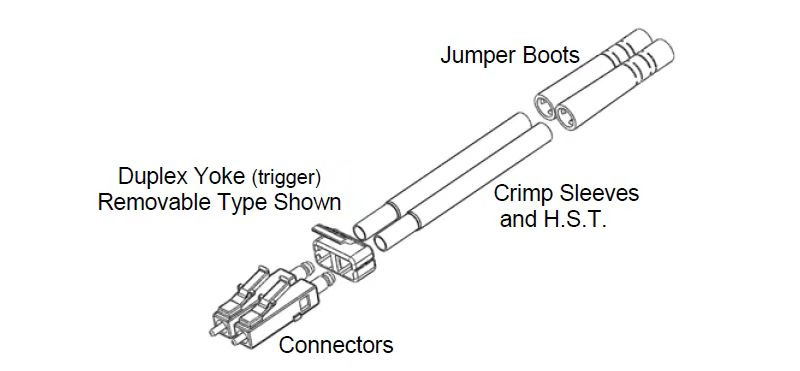

MTP/MPO Fiber Connector

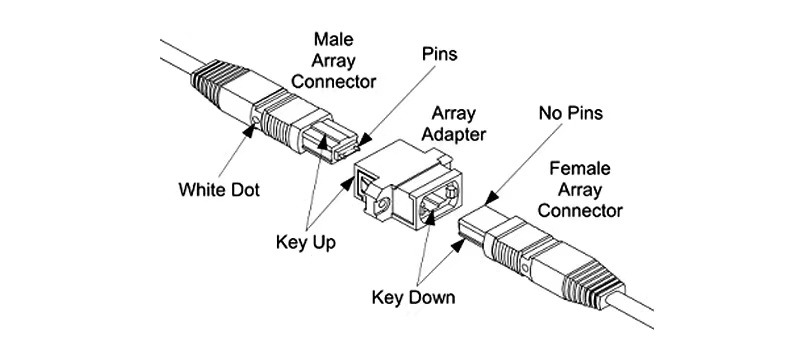

The MPO (Multi-Fiber Push-On) connector is the preferred choice for ultra-high-density applications due to its complex design that supports multiple fiber connections. Typically, it arranges 12 fibers in a single row and can accommodate one or more rows of fibers within the same MPO connector, significantly increasing connection density per unit of space. MTP is an enhanced version of the MPO connector, featuring structural optimizations while maintaining full compatibility with MPO. Functionally, there is no difference between the two in practical use. Because of their complex structure and multi-fiber integration, MPO/MTP connectors have higher costs and shorter service lives. Nevertheless, they remain the leading choice for ultra-high-density cabling and are widely used in environments requiring dense fiber optic deployments.

Comparison of Fiber Connector Usage Scenarios

There are many scenarios for network cabling, and different fiber optic connectors need to be selected in different scenarios to better meet our needs. Among the scenarios where fiber optic connectors are used, there are three scenarios that have the greatest impact on the choice of fiber optic connectors: wiring density, service rate, and usage environment. Together, they determine what kind of fiber optic connector to choose.

High-Density Cabling Usage Scenarios

When cabling density is high, both cost and size become critical factors. High costs tie up budget resources, while larger connector sizes can limit available space for cabling. Therefore, small-form-factor LC connectors and high-density MTP/MPO connectors are the top choices for such environments.In contrast, when cabling density is low, space constraints are less of an issue and cost sensitivity decreases. Under these conditions, a wide range of fiber optic connectors can be selected to meet connectivity needs without compromising on performance.

High-Rate Usage Scenarios

High-speed applications are primarily dominated by MPO and LC fiber connectors, with LC fiber connectors being the most widely used. While MPO connectors support high data rates, their higher cost makes long-distance transmissions expensive. On the other hand, LC connectors, combined with wavelength-division multiplexing (WDM) technology, enable multiple wavelengths to be transmitted over a single fiber. This significantly conserves fiber resources and reduces overall deployment costs.

Industrial Environment Usage Scenarios

In industrial production environments, vibration is unavoidable. To ensure long-term stable operation of fiber optic connections under such conditions, only FC connectors with screw-lock mechanisms can reliably meet these demands. Their secure fastening helps maintain uninterrupted network performance, safeguarding production processes from costly downtime.

Conclusion

This article introduces in detail the technical parameters and usage scenarios of LC, SC, FC, ST, and MTP/MPO fiber optic connectors, and compares their advantages and disadvantages. I believe that after reading this article, my friends will have a preliminary understanding of them and will be more targeted when making choices. Pay attention to LSOLINK, we will bring you more useful knowledge.