OM1 vs OM2 vs OM3 vs OM4 vs OM5 Fiber: Multimode Fiber Types Explained

Basics of Multimode Fiber: Why Need to Divide OM Levels?

In short-distance high-speed communication scenarios such as data centers and local area networks, multimode optical fiber plays an important role due to its low cost and easy installation. In the face of ever-escalating bandwidth requirements, multimode optical fiber is also constantly improving. The differences and specific application scenarios of different multimode optical fibers will be introduced in detail below.

Core Principles and Optical Signal Transmission Mechanism

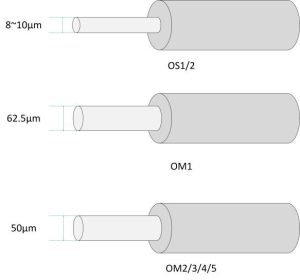

The core characteristic of multimode fiber is that the core is thicker. In the article “Everything You Need to Know Single Mode Fiber Optic Cable“, the characteristics of single-mode fiber are detailed and compared with the core of multimode fiber. The core diameter of multimode optical fibers is usually 50μm or 62.5μm. As the name suggests, multimode fiber allows multiple optical transmission modes to exist simultaneously. When the light beam emitted by the light source enters the fiber core, light rays with different incident angles will propagate through different paths. The characteristics of this multimode transmission are significantly different from those of single-mode fiber with a single path, and it also brings corresponding technical challenges – modal dispersion.

Modal Dispersion and Bandwidth Limitation

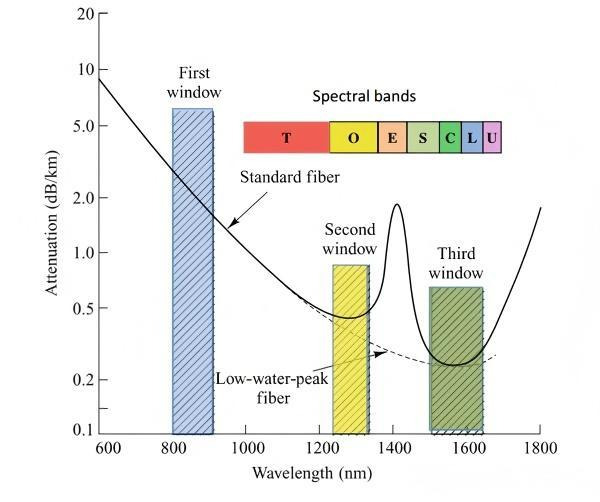

Modal dispersion is the core factor that constrains the performance of multimode optical fibers. Due to the fact that light is incident at multiple angles, multimode optical fibers form different propagation modes, each with different axial velocities. As these modes arrive at their endpoints at different times, as shown in the figure below, they can cause pulse broadening and signal distortion. This phenomenon is called modal dispersion. When the pulse broadening exceeds the resolution of the receiving end, errors occur, thereby limiting the available bandwidth and transmission distance of the fiber.

Taking the early OM1 fiber as an example, its bandwidth distance product at 850nm wavelength is only 200MHz · km, which cannot meet the requirements of modern 10 Gigabit Ethernet. Subsequent OM grades have gradually improved bandwidth performance by optimizing the fiber core structure. The commonly used OM4 fiber now has a bandwidth distance product of 4700MHz · km at 850nm wavelength, supporting 10Gbps signal transmission at 550m.

OM Grading Standard

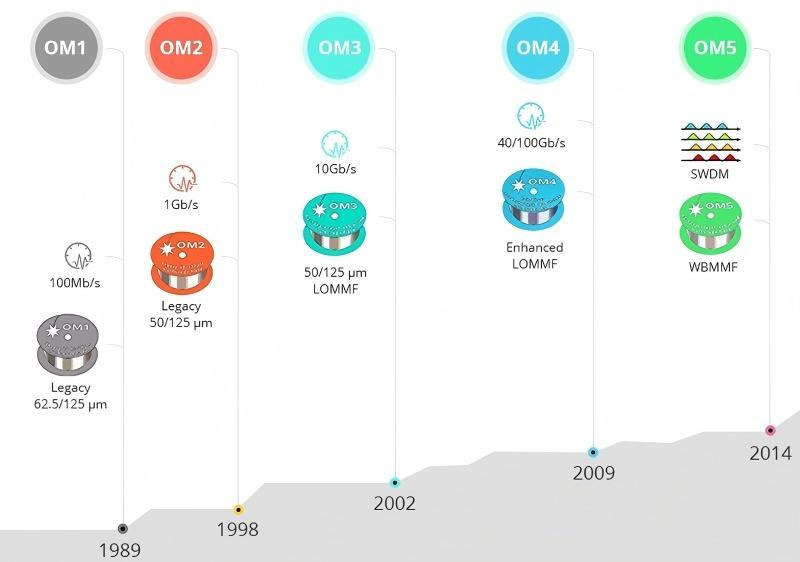

The classification of OM levels originates from the TIA/EIA-492 standard system and is constantly updated with the development of optical communication technology. Early OM1 fibers mainly had a core diameter of 62.5μm and were suitable for LED light sources, with limited bandwidth performance. The major breakthrough of OM2 is to improve the core diameter to 50μm and increase the wavelength bandwidth of 850nm to 500MHz · km by optimizing the distribution of gradient refractive index. OM3 adopts a core diameter of 50μm, matched with the narrow spectral characteristics of VCSEL light source, and supports 10Gbps signal transmission. OM4 has nearly doubled its bandwidth by further optimizing coating materials and manufacturing processes, meeting the bandwidth requirements of 40/100G Ethernet. OM5 fiber is designed for future high-speed scenarios and supports short wave division multiplexing (SWDM) technology. It can transmit 4 parallel signals within the wavelength range of 850-953nm.

Full Analysis of Technical Parameters from OM1 to OM5

OM1 Fiber Optic

OM1 is the earliest commercial multimode fiber standard, mainly using a 62.5μm core diameter and a 125μm cladding step or gradient structure. In the early days, LED was used as the light source, laying the foundation for multimode fiber. The large core diameter can mainly reduce the difficulty of coupling the light source and lower the construction cost. On the contrary, the limitation it brings is limited bandwidth. At a wavelength of 850nm, it only supports short distance transmission at a rate of 100Mbps. At a wavelength of 1300nm, due to the low efficiency of the LED light source used at long wavelengths, its practical application is limited.

OM2 Fiber Optic

The OM2 standard was released in 1998, which first established a gradient fiber with a core diameter of 50μm and a cladding of 125μm. By optimizing the refractive index distribution and core diameter to reduce the number of transmission modes, the modal dispersion was reduced by about 40%, and the bandwidth at 850nm was significantly improved compared to OM1, supporting signal transmission at 1Gbps over 550m. And it maintains the advantages of multimode fiber, easy to fuse and install, and low cost. Widely used in data center distribution rooms and campus network backbone links, it has become the main cable of the gigabit era.

OM3 Fiber Optic

OM3 fiber introduces the concept of “effective mode bandwidth” and uses VCSEL light source to further optimize the distribution of refractive index in the fiber core based on its narrow spectral characteristics, making high-order mode transmission more balanced. Compared to OM2’s 550m transmission at 1Gbps, OM3 achieved 300m transmission at 10Gbps, meeting the high-speed interconnection needs of data centers at that time and marking a breakthrough in the 10Gbps era.

OM4 Fiber Optic

On the basis of OM3, OM4 increases the bandwidth to 2.35 times that of OM3 through more precise preform manufacturing processes, and supports 4-channel parallel 10Gbps or 10 channel parallel 10Gbps signal transmission. At a speed of 100Gbps, compared to OM3’s 100m transmission distance, OM4 provides stable transmission of 150m, which is more suitable for large-scale network layouts and is backward compatible with OM3, making system upgrades easier.

OM5 Fiber Optic

OM5 fiber was first proposed in 2014, and TIA began to initiate WBMMF standardization work. In 2016, TIA released ANSI/TIA-492AAAE, and ISO/IEC officially named OM5. OM5 fiber optic expands the wavelength range (850~953nm) by using SWDM technology, supporting single fiber 4-channel wavelength transmission, which can reduce data center cabling density. By improving the cladding material, the minimum bending radius is reduced from 15mm to 7.5mm, making it suitable for higher density cabling environments.

| Technical Parameter | OM1 | OM2 | OM3 | OM4 | OM5 |

| Publication Year | 1980s | 1998 | 2003 | 2009 | 2016 |

| Outer Sheath Color | Orange | Orange | Blue Green, Lake Blue | Teal, Violet | Apple Green |

| Core Diameter/Cladding Diameter | 62.5μm/125μm | 50μm/125μm | 50μm/125μm | 50μm/125μm | 50μm/125μm |

| Typical Working Wavelength | 850nm,1300nm | 850nm,1300nm | 850nm | 850nm,953nm (Supports dual wavelength) | 850nm,880nm,910nm,940nm (Supports dual wavelength) |

| Light Source | LED | LED | VSCEL | VSCEL | VSCEL |

| Bandwidth Distance Product (850nm) | 200 MHz·km | 500 MHz·km | 2000 MHz·km | 4700 MHz·km | >3500MHz·km (Single wavelength) |

| Maximum Transmission Rate | 100Mbps | 1Gbps | 10Gbps | 100Gbps | 400Gbps |

| Outer Sheath Material | Quartz glass core+acrylic coating | Pure quartz core+low loss coating | Temperature resistant coating (-40℃~85℃) | Germanium doped quartz core+low refractive index cladding | Ultra low bending loss (radius ≤ 7.5mm) |

| Application Scenarios | Short distance LAN, fiber to desktop | Enterprise network, campus network | Data center, high-performance computing | High density data center, cloud computing | High density data center, wavelength division multiplexing (SWDM4), 5G base station |

Innovation in Physical Structure and Materials

Changes in Fiber Core Diameter

According to the previous comparison table, it can be seen that the fiber core diameter has changed since OM2, and the core diameter of 50μm is still used today. The 62.5μm core diameter of early OM1 was mainly designed to adapt to mature LED light sources and reduce coupling difficulty, but the large core diameter resulted in severe modal dispersion, thereby limiting bandwidth. Starting from OM2, the 50μm core diameter makes the fiber propagation path more uniform and significantly reduces modal dispersion. Subsequent OM3 to OM5 continue this core diameter and focus on optimizing the cladding and SWDM technology to improve core utilization.

Selection of Materials and Coatings

In terms of material selection, OM1 to OM5 have gradually upgraded from ordinary quartz glass to germanium doped quartz glass. Germanium element can finely adjust the refractive index distribution, reduce propagation loss, and make the mode more stable. The high-purity germanium doped quartz cores of OM4 and OM5, combined with precision technology, reduce the wavelength attenuation of 850nm to below 0.35dB/km. In terms of coating, both OM1 and OM2 use traditional acrylic coatings, which have poor performance in high temperature and high humidity environments. OM3 introduces a heat-resistant coating, which extends the working temperature range to -40~85°C and is suitable for industrial environments. OM4 and OM5 use low refractive index and high flexibility coatings to increase transmission distance and reduce bending radius, meeting the high-density cabling requirements of data centers.

Connector Compatibility

The compatibility of multimode fiber optic connectors is also crucial for engineering deployment. In the early days, OM1 used large-sized connectors such as ST and SC, but later miniaturized LC connectors became mainstream. OM2 to OM5 are fully compatible with LC interfaces, and there is no need to replace connectors when upgrading, reducing the cost of transformation. In high-speed scenarios such as 40G and above, MPO connectors are required to ensure network stability. OM3 to OM5 are compatible, and when upgrading to 400/800G networks in data centers, existing cabling facilities can be reused, reducing cabling costs.

Scenario Based Selection Guide

Traditional Network Upgrade Scenarios

Applicable objects: Low speed network renovation of old campus networks and enterprise office buildings.

Core requirement: Low cost reuse of existing cabling to meet 1Gbps or 10Gbps data transmission.

Recommended models: OM2 or OM3.

- OM2: If the existing wiring is OM1, it can be directly replaced with OM2 to increase the 1Gbps data transmission distance from 300m to 550m;

- OM3: If you need to upgrade to 10Gbps speed, prioritize OM3 fiber jumpers to reserve space for future upgrades.

Short Distance Interconnection of Data Centers

Applicable objects: Inter rack connections, internal communication of blade spine architecture.

Core requirements: High speed (10G/40G/100G), high-density cabling.

Recommended model: OM4.

- OM4: Achieve 100Gbps transmission within 100 meters and support 40Gbps within 500 meters, making it the mainstream choice for data centers with high cost-effectiveness;

- OM5: Suitable for ultra high speed scenarios of 400G and above, using SWDM4 technology to transmit 4 signals through a single fiber optic cable, reducing wiring density, suitable for new construction or large-scale upgrade projects.

Industrial Environment Application

Applicable objects: smart factories, automated production lines, industrial Internet of Things (IIoT).

Core requirements: high stability, wide temperature tolerance, and resistance to electromagnetic interference.

Recommended model: Industrial grade OM3/OM4.

- OM3: The heat-resistant coating can work in an environment of -40~85°C, support 10Gbps transmission, and meet the needs of most industrial scenarios;

- OM4: If higher bandwidth is required, OM4 can provide longer transmission distance and bending resistance.

5G Fronthaul Network

Applicable objects: Medium to short distance connections between base stations and aggregation nodes (300-500 meters).

Core requirements: multi wavelength multiplexing, low latency, high reliability.

Recommended model: OM5.

- OM5: OM5 supports 850-950nm multi wavelength transmission and is compatible with SWDM4 technology for 5G fronthaul, which can reduce fiber usage, deployment complexity, and cost.

| Requirement | Traditional network upgrade | Short distance data center | Data Center 400G+ | Industrial environment | 5G fronthaul network |

| Transmission rate requirements | 1G/10G | 40G/100G | 400G/400G+ | 10G/40G | Multi-wavelength Parallel |

| Distance | ≤300m | ≤150m | ≤500m | ≤500m | 300-500m |

| Cost sensitivity | High | Medium | Low | Medium | Medium |

| Recommended OM level | OM2/OM3 | OM4 | OM5 | OM3/OM4 | OM5 |

The Development Trend of Multimode Optical Fiber

With the rapid development of the communication industry, multimode fiber is accelerating its evolution towards the integration of ultra-high speed and intelligence. On the one hand, breakthroughs in bandwidth performance are still the core direction to meet future data transmission rates of 1.6Tbps or even higher. On the other hand, further optimization of modal dispersion and signal attenuation can effectively reduce signal distortion in multimode transmission. With the rapid growth of the demand for low latency and high-density connections in the metauniverse, edge computing, etc., multimode fiber will continue to consolidate its core position in the field of short-range high-speed communication.

FAQ

Q: What does the color design of the outer sheath of multimode fiber mean?

A: The outer sheath color of multimode fiber is specified by the international TIA 568C standard: OM1 is orange, OM2/OM3/OM4 is teal (in some areas, OM4 is violet), and OM5 is apple green. Color identification facilitates quick differentiation of fiber types during engineering deployment, avoiding connection errors.

Q: What factors affect the transmission distance of multimode optical fiber?

A: Mainly constrained by bandwidth distance product, transmission rate, and light source type. For example, OM3 has a 10Gbps transmission distance of 300 meters at a wavelength of 850nm. If it is reduced to 1Gbps, the transmission distance can be extended to over 1000 meters, but it also needs to be adapted to specific modules.

Q: How to choose OM3 and OM4 optical fibers in practical applications?

A: If only 10Gbps data transmission is required, OM3 has a higher cost-effectiveness within 300 meters; If it involves a 40G/100G speed or requires a transmission distance exceeding 300 meters, OM4 can ensure stable transmission with a higher bandwidth distance product and reserve upgrade space for the future.

Q: What is the biggest advantage of OM5 fiber compared to OM4?

A: OM5 supports SWDM technology and can transmit 4 signals simultaneously, which can significantly reduce wiring density. However, without an adaptation module, its cost is not recommended. Conventional OM4 can meet most needs.