SFP+ Direct-Attach Cable Overview and Helpful Insights for You

Cable Overview

High-speed cables are cable assemblies with fixed connectors at both ends. The connectors used are the same as the interfaces of optical modules, but compared to optical modules, high-speed cables do not need to be matched with jumpers, and DAC connectors do not have expensive optical lasers, which greatly saves costs and power consumption, becoming a low-cost and high-efficiency high-speed data communication solution to replace optical modules.

Cable Classification

Passive Copper Cable

The connector of the passive direct-attach copper cable does not contain active components. The passive direct-attach copper cable provides a direct electrical connection between the corresponding cable ends, which can reach a transmission distance of 7m at a data rate of 10Gbps with low power consumption.

Active Copper Cable

The connector of the active direct-attach copper cable contains active components and driver chips (linear amplifiers) for transmitting and receiving electrical signals. These active components help improve signal quality and provide longer cable distances, reaching a transmission distance of 15m at a data rate of 10Gbps with low power consumption.

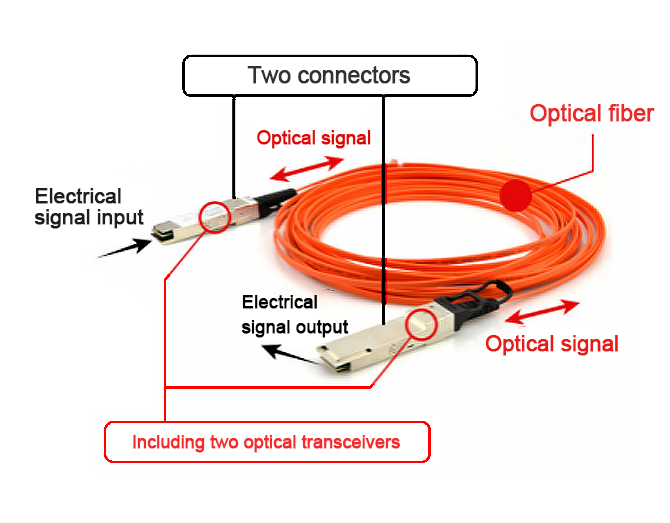

Active Optical Cable

AOC is made of optical fiber, and its connector contains active components such as post-amplifier and laser driver. Therefore, the transmission distance of AOC is much longer than that of passive direct copper cable and active direct copper cable. Usually, active optical cable can transmit signals up to 300m.

Internal structure of DAC and AOC

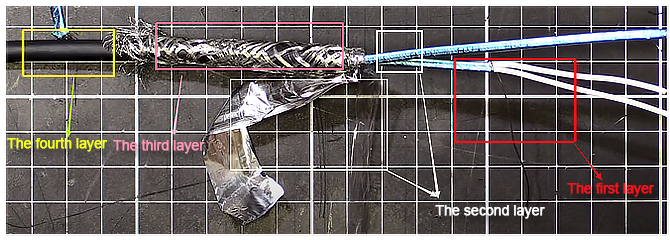

DAC Internal Structure

First layer: wrapped core wire. Two insulated core wires and ground wire are combined together, wrapped with a layer of aluminum foil and a layer of self-adhesive polyester tape.

Second layer: cabled core wire. It is composed of two or more wrapped core wires, also wrapped with a layer of aluminum foil and a layer of self-adhesive polyester tape.

Third layer: metal shielding mesh. It is used to enhance the shielding effect of the wire and obtain better performance.

Fourth layer: outer sheath made of polyethylene material.

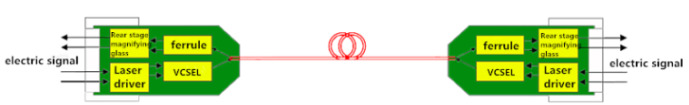

AOC Internal Structure

AOC is a fiber optic patch cord with optical transceivers at both ends, which requires external energy to complete the mutual conversion of optical/electrical signals.

As a main transmission medium for high-performance computers and data centers, active optical cables ensure the stability of transportation and the flexibility of application, and are more common in high-density applications.

Straight Cable and Branch Cable

Straight Cable

A direct-attach cable is a connector with the same packaging specifications at both ends. It is mainly used for direct connection of ports with the same speed of devices in the same cabinet or adjacent cabinets. This type of cable has two main applications, namely business data transmission and device stacking.

Business transmission: refers to the exchange of data between two devices. 1-15m can be used in use.

Device stacking: Two or more devices are virtualized into a switch through stacking technology. The cables generally used are relatively short, usually not exceeding 5m.

Note: Cables can be used for stacking in business ports, but cannot be used for dedicated stacking ports of devices. Professional stacking ports require professional stacking cables.

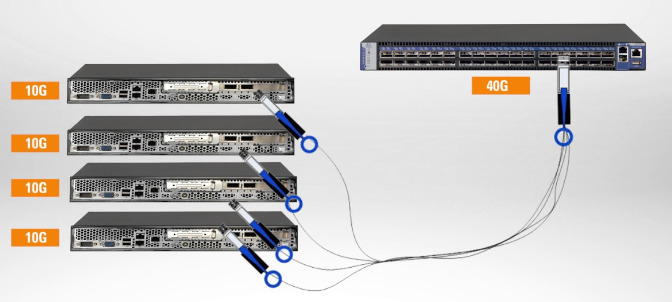

Branch Cable

Branch cables are different from direct lines. Both ends of the branch line have different packaging specifications and are mainly in a one-to-many form. They are mainly used for direct connection of ports with different speeds of devices in the same cabinet or between adjacent cabinets. This type of line is mainly used for connection between switches and server network cards.

AWG Wire Gauge

AWG (American Wire Gauge) is a measurement system used to standardize the diameter, cross-sectional area and current carrying capacity of wires. It is widely used in electrical engineering, communications and electronics in North America.

Definition: It is a standard for distinguishing wire diameters.

Characteristics: The larger the AWG value, the smaller the wire diameter, the thinner the wire, and the greater the signal loss.The value in front of AWG (such as 24AWG, 30AWG) indicates the number of holes that the wire must pass through before forming the final diameter. The larger the value, the more holes the wire passes through, and the smaller the diameter of the wire.

Note: AWG is used to measure wires, not optical fiber wires, so AOC has no AWG distinction.

AOC vs DAC

The Advantages of DAC

- In terms of transmission distance: Compared with active optical cables, DAC high-speed cables have a shorter transmission distance and are suitable for short-distance wiring in data centers.

- In terms of material: the interior of DAC high-speed cables is made of copper core. Copper cables act as natural heat sinks, have good heat dissipation effects, and are energy-saving and environmentally friendly.

- In terms of power consumption: DAC high-speed cables have low power consumption. Since passive DAC does not require power, the power consumption is almost zero; the power consumption of active DAC is generally around 440mW. Compared with the 2W of active optical cables, DAC cables have certain advantages in terms of energy consumption.

- In terms of cost: the price of copper cables is much lower than that of optical fibers. Therefore, using DAC high-speed cables will also reduce the wiring cost of the entire data center.

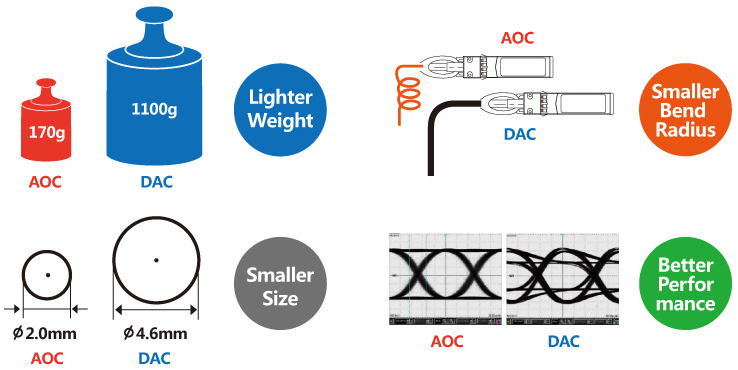

The Advantages of AOC

- Lightweight: AOC uses optical fiber (glass or plastic fiber) to replace the copper conductor of DAC. The density of optical fiber (about 2.2-2.6g/cm³) is significantly lower than that of copper (8.96g/cm³), which directly reduces the weight of the cable. For example, a 10-meter 40Gbps AOC weighs only about 200 grams, while a DAC of the same specification can weigh more than 500 grams.

- Smaller bending radius: The bending radius of optical fiber can reach 10 times its outer diameter (for example, a 3mm outer diameter AOC can be bent to a radius of 30mm), while a DAC requires at least 15 times the wire diameter due to the ductility limitation of the copper conductor (for example, a 6mm outer diameter DAC needs to be bent to a radius of 90mm).

- Small wire diameter: The outer diameter of a typical 40Gbps AOC is about 3.0-4.5mm, while the outer diameter of a DAC is 5.0-7.0mm due to the cross-sectional area requirements of the copper conductor (such as 24AWG twisted pair).

- Better bit error rate: Optical fiber transmits optical signals and is completely immune to electromagnetic interference (EMI) and radio frequency interference (RFI), while DAC copper cables are susceptible to interference from power lines, motors, etc., resulting in increased bit error rate (BER).

The Application Scenarios of SFP+ Cables

10G SFP+ DAC and AOC cables are widely used in data centers to connect servers, storage devices, and switches. They usually play a key role in the following two application scenarios.

Connection between servers and switches. This cable plays a core role between 10G ToR switches and servers, or in stacking 10GbE switches. Due to its 7-meter link length, low power consumption, low latency, and low cost, it is ideal for short-distance server-switch connections.

Connection between switches. This cable supports longer distance connections and is suitable for multiple locations in the data center, such as ToR, EoR, and MoR. Therefore, 10G SFP+ AOC cable assemblies are high-performance and cost-effective I/O solutions for 10G Ethernet and 10G Fibre Channel applications. Due to its theoretical maximum transmission distance of up to 100 meters, this cable is often used for switch-to-switch connections.

How to Choose the Most Suitable SFP Cable

According to the Transmission Distance

When choosing 10G SFP+ cables, we need to pay attention to the distance requirements. If the distance is ≤7 meters, we can choose DAC copper cable, if the distance is ≤15 meters, we can choose ACC copper cable, and if the distance is 7~100 meters, we can choose AOC optical cable.

According to the Manufacturer’s Strength

When producing SFP+ cables, manufacturers will conduct various tests on SFP+ cables, such as aging test, high and low temperature test, reliability test, real machine flow measurement, etc. If the SFP manufacturer can provide test reports for these projects, it means that their products have undergone rigorous testing and the quality is guaranteed. LSOLINK’s products have all passed the 4-layer quality firewall system (production line self-inspection and mutual inspection, IPQC, OQC, OBA), and each product can provide an independent test report.

According to AWG Wire Gauge

AWG wire gauge is a standard for distinguishing wire diameters. The larger the AWG value, the smaller the wire diameter. The thinner the wire, the greater the signal loss. For example, there are two 10G SFP+ 5m DACs, one is 28AWG and the other is 30AWG. The 28AWG wire diameter is thicker than the 30AWG wire. The thicker the wire, the smaller the loss. The smaller the loss, the higher the signal quality.

According to Certification

When purchasing SFP+ cables, choose those with RoHS, CE, and FCC certification marks to ensure that the cables meet international standards in terms of environmental protection, electromagnetic compatibility, safety, etc. SFP cables that have not passed the international system may cause equipment short circuits, which may affect business transmission at the least, or even cause fire risks.

According to Compatibility

To prevent potential problems in the data center, multiple brands of equipment will not be used in the computer room, including Cisco, Aruba, Juniper, etc. These brand devices are encrypted so that they can only use their own brand of SFP+ cables. Cisco brand SFP cables cannot be used on Aruba devices, and vice versa, Aruba cables cannot be used on Cisco devices. In order to deal with this situation, it is particularly important to choose an SFP that is compatible with both Cisco and Aruba. LSOLINK’s SFP cables can support multiple compatible customizations, allowing you to easily connect devices of different brands.

How to Install and Remove SFP+ Cables

Installing SFP+ Cables

- Remove the SFP+ cable from the anti-static container and remove the dust cover from the connector.

- Align the SFP+ cable with the SFP+ port on the device.

- Gently push the module straight in until you hear a click and it is fully inserted into the port.

Removing the SFP+ Cable

- Hold the SFP+ cable.

- Gently pull the pull ring on the cable to pull out the SFP+ cable.

SFP+ Cable Usage Precautions

Avoid excessive bending: The minimum bending radius of DAC and ACC is 0.5 meters. Excessive bending of SFP+ copper cables will cause serious signal attenuation and bit errors. The minimum bending radius of AOC is 30mm. Bending SFP+ AOC will destroy the physical phenomenon of total internal reflection of light in the optical fiber. Excessive bending will cause optical signal loss or fiber breakage.

Do not pull or squeeze:Pulling will cause the connection between the cable and the module to loosen, affecting the stability of signal transmission; avoid heavy objects on the cable, which may cause deformation of the copper cable and optical fiber, or even internal breakage.

Anti-static:The working voltage of SFP+ cable is 3.3V. The instantaneous voltage generated by static electricity can reach tens of thousands of volts, which may cause short circuit of electronic components in the SFP+ cable.